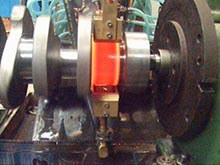

Crankshaft hardening

2016-01-10

Nodular cast iron crankshaft fillet rolling strengthening technology is widely applied to the crankshaft processing.

the round corner rolling strengthening and shaft neck surface quenching composite strengthening technology will also be a large number of applied to the crankshaft machining, forging steel crankshaft strengthening way will be more use of journal fillet hardening process.

The steel or iron is heated to a temperature above the critical point, holding time

Then in water, brine or oil (individual material in air) rapidly cooled down to obtain a high hardness.

Used to increase hardness and strength limit steel or iron.